Here at Rotolok we are always looking to add safety features while minimising the space required. An example of this is when a client came to use to help them improve their plants design while maintaining safe functionality.

The client had a hazardous and arduous process for the internal inspection of valve condition for maintenance and function. This was a major problem as they were handling abrasive products such as dry beans and grains, so they were performing this regularly. They required a solution to make the necessary inspection less time consuming and safer for the operators.

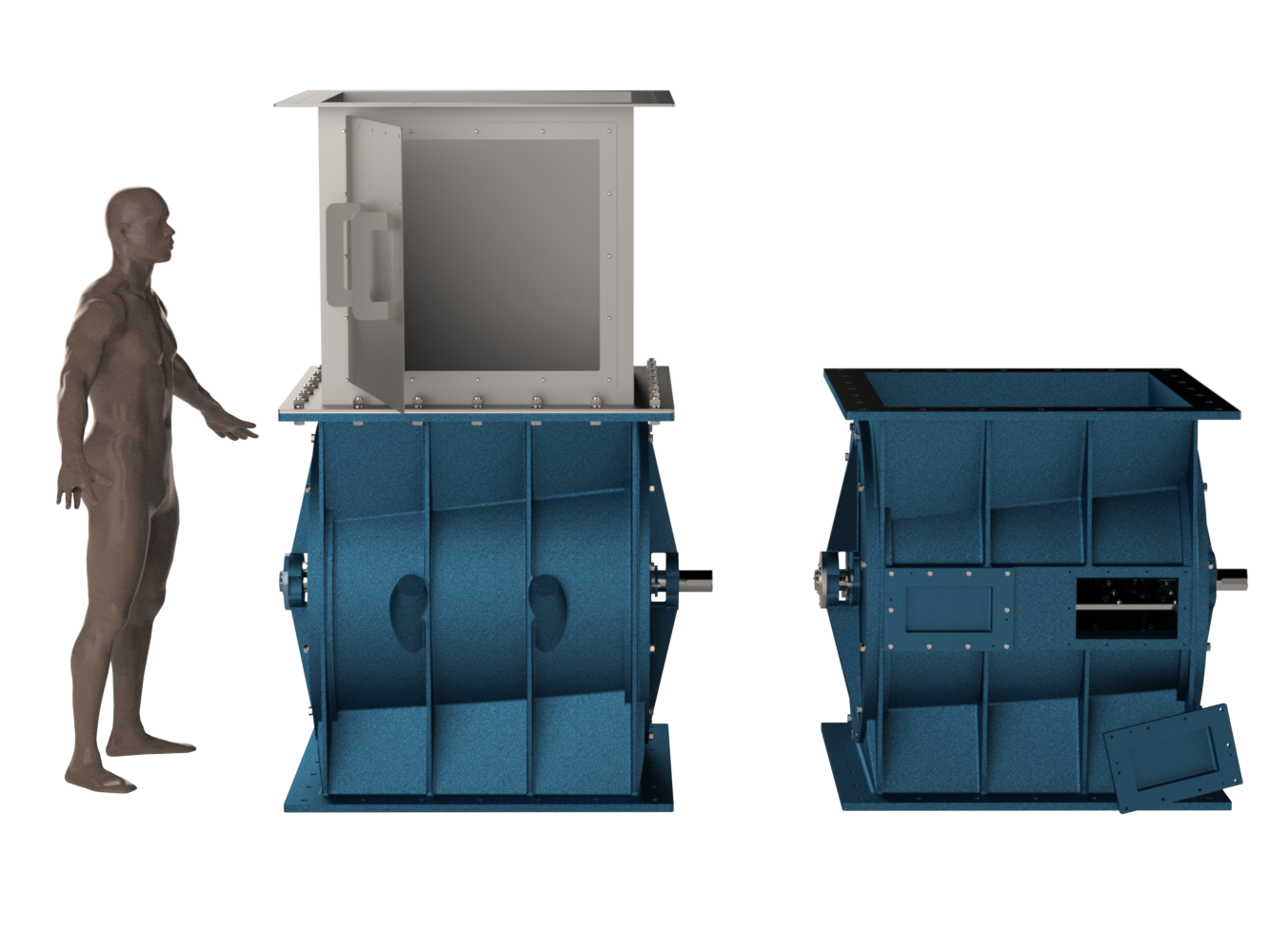

We incorporated interlocking inspection apertures in the cast body of the valve. This resulted in safer operating conditions, reduced time spent on maintenance and inspection, reduced cost with simplification of ductwork. The 915 mm Rotary Valve with inspection apertures gives a reduction in installation height of approximately 1 metre.

(Pictured: A 3D model rendering of the previous system and the new one supplied by Rotolok)

Back to News