The Flexible sleeve valve has proved itself over a number of years as a simple, reliable isolation or variable feed control valve on applications in the powder or air handling industries – its simplicity being its major advantage.

The basic construction is a fabric sleeve that, with each end being held firmly to a circular shape on rotation through 180°, will seal against the very finest of powders.

Partial rotation leads to partial opening and a multitude of different types of sleeve can be accommodated, the better type of sleeves are food quality nylon, impregnated cloth. These types of sleeves are weighty, give the valve good full opening properties.

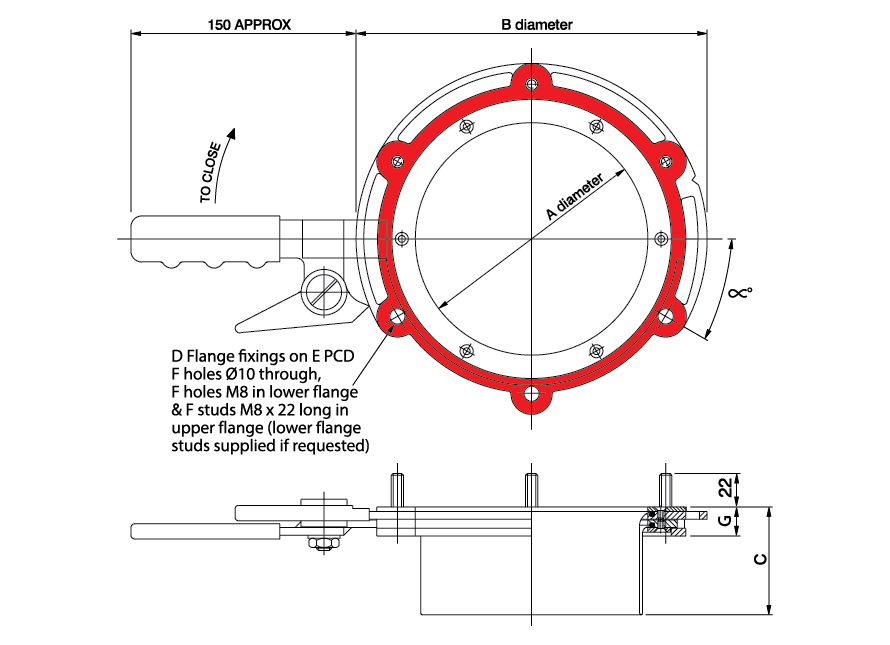

Cast Rotoflex Iris

The Rotoflex is cast in aluminium or stainless steel. It is a high duty, hand operated valve for fine powders on open discharge systems. The Rotoflex lends itself particularly on filling applications. The sleeve is fixed with clamping rings. It can also be used on in-line systems but care must be taken to ensure mating gasket or flange does not interfere with rotating clamping ring. The main advantage of the Rotoflex is that it can be retensioned ‘insitu’.

Fabricated Slimflex Iris

The Slimflex is a low cost alternative to the Rotoflex, designed primarily for the needs of the IBC market. It is manufactured from mild or stainless steel laser cut rings providing a robust, yet lower duty valve. Mild steel parts are zinc coated. The advantage of the Slimflex is that any size can be accommodated.

Double Sleeve Option

It is available on Rotoflex and Slim flex. It gives the added advantage of complete sealing to the working components and is therefore in ‘in-line’ systems, completely dust tight which is a valuable aid with most powder and air handling systems up to 28” w.g. The doubling effect of the sleeve gives good sealing qualities.

All dimensions are in mm unless otherwise stated

| SIZES | A | B | C | D | E | F | G | ∞° |

|---|---|---|---|---|---|---|---|---|

| 100 | 102 | 184 | 61 | 4 | 156 | 2 | 19 | 45° |

| 150 | 152 | 230 | 86 | 6 | 203 | 3 | 19 | 30° |

| 200 | 203 | 280 | 111 | 6 | 254 | 3 | 24 | 30° |

| 250 | 254 | 350 | 137 | 8 | 327 | 4 | 24 | 22.5° |

| 300 | 305 | 400 | 162 | 8 | 378 | 4 | 24 | 22.5° |

| 350 | 356 | 450 | 195 | 12 | 426 | 6 | 24 | 15° |

| 380 | 381 | 475 | 116.5 | 12 | 451 | 6 | 24 | 15° |

| 400 | 406 | 500 | 220 | 12 | 476 | 6 | 24 | 15° |

| 450 | 457 | 551 | 250 | 16 | 527 | 8 | 24 | 11.25° |

Restricted Content

This page contains content that is available to registered users only.

To view the restricted content, please log in or create an account to gain access to view the resources.

Login

Register for account

Register* Once your account has been approved , your password will be autogenerated and emailed to your registered e-mail address